News & Views

News & Views

We all know change is inevitable – tech continues to make headway, and so do our safety expectations. Given that the current AS/NZS 3439 standard first came into play in 1998, there have been many advancements in electrical switchgear, design, manufacture, and safety processes. The updated standard also stands to refine financial and legal duties across specification, testing, and design. On top of this, it seeks to strengthen transparency between manufacturers and users.

The AS/NZS 61439 are a set of standards for low voltage switchgear and control gear assemblies. Replacing AS/NZS 3439, the new standards follow the IEC 61439 set and include ‘in-country notes’ particular to Australia and New Zealand.

AS/NZS 3439 was redundant as of May 2021 when AS/NZS 61439 replaced it as the only option. It has eight parts including low-voltage switchgear and controlgear assemblies:

If you’re upgrading a current switchboard built to old standards – replace like-for-like electrical parts. If you’re altering the switchboard itself, upgrade that section to the new benchmark – this may mean an entirely new switchboard.

The outstanding reasons for the shift were to address the following five inconsistencies found in AS/NZS 3439:

AS/NZS 61439 holds construction, performance and suitability of devices and components to full measures. This helps reduce risk and confirm the safety of power distribution boards across residential, commercial, and industrial contexts. But of course, a standard is just a standard until it’s applied, so let’s look at how the changes land.

Temp Climbs

For certification, the AS/NZS 61439 outlines a temperature rise test. In the old standard, temperature rise limits for all components and busbar systems within the enclosure was 105°C. Now the maximum ambient temperature factors and calibrates around this: the main busbar can operate at 105°C above the ambient temperature. This means more current carrying capacity but also a greater toll on mechanics and copper lifespan.

Copper ‘softens’ above 150⁰C and under short circuit can tolerate up to 250⁰C for a few seconds; it works well at 105⁰C for periods of 25 years. So, as a general rule, look at these lifespan values for busbar vs operating temps: 105⁰C = 20 to 25 years, 110⁰C = 17 to 20 years, and 130⁰C = 11 to 18 years.

Limit temp rise in the inclusive design of the assembly and verify temp rise by testing within the same main switchboard.

Device Substitution

The new switchboard standards direct the complete assembly is verified to comply. The person making any design adjustments is then accountable for the change and must ensure the revised assemble complies – not the manufacturer. In addition, when a switchboard manufacturer creates a new system, they’re obliged to test it with multiple devices.

Arc Fault Mitigation

This notion aims to curb the likelihood of an internal arcing fault, any resulting injury or damage to equipment rendering it unusable. The containment test conditions are more detailed and practical, which ensures a higher level of safety.

Without many repercussions in the commercial or contracting space, the main impact of AS/NZS 61439 is on testing procedures and switchboard design for manufacturers. The standards also lay out clear liabilities for switchboard manufacturers from a safety, legal and financial perspective.

Every switchboard needs compliance documentation to prove its functioning features satisfy or surpass the requirements for the installation outlined in AS/NZS 61439. This documentation has two parts: Design Verification and Routine Verification. Verify the features by test, comparison or assessment.

Make sure you don’t underestimate the complexity of AS/NZS 61439 by taking parts of it out of context. To ensure your building or facility is compliant – call our qualified electrical team. As compliant solutions providers, we’ll assess your site and provide recommendations.

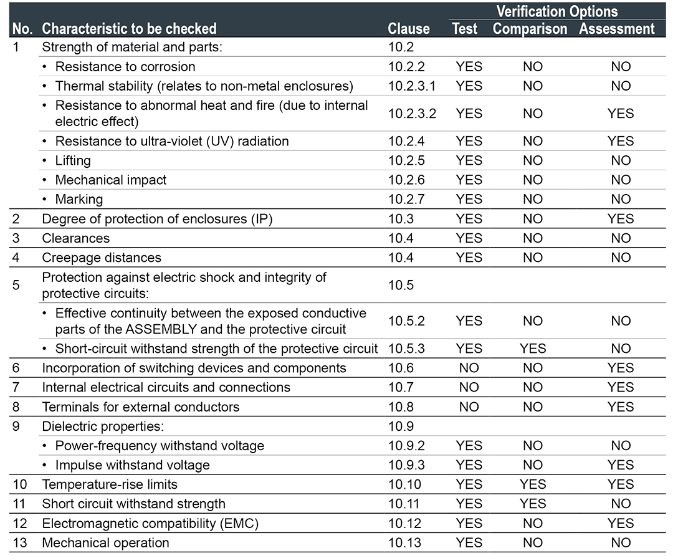

All final assemblies should meet or exceed the standard’s constructional and performance requirements. See Annex D, design verification Table D1 of the standard below for more details about the 13 design and performance characteristics:

To verify the characteristics identified in Table D1, you can use the three verification methods below. Refer to Table D1 to know which verification methods you can or can’t use for each of the 13 constructional and performance characteristics.

1. VERIFICATION BY TEST (previously known as Type Test)

An assembly or parts of assemblies undergo a test to check whether the design satisfies the requirements. (Note: Further verification of these requirements is no longer required if the best results fulfil the requirements of the relevant part of the AS/NZS 61439 series upon conducting a test in accordance with IEC 60439, IEC 61439 or the AS/NZS 3439 series.)

2. VERIFICATION BY COMPARISON

The tester compares the switchboard or relevant section of the switchboard to a test-verified reference design. A test-verified reference design is a switchboard that has passed a test. If the new board’s elements match the tested reference design, it is compliant by comparison.

3. VERIFICATION BY ASSESSMENT

The application of design rules and calculations, including appropriate safety margins, undergo a strict verification assessment to confirm whether they comply with the standard.